What is JIT?

Just-in-Time (JIT) inventory management is a strategy where businesses receive stock only when needed, minimizing excess inventory and storage costs. It focuses on efficiency, ensuring materials arrive precisely when required. In this blog, we’ll explore how JIT works, its advantages, real-world examples, and best practices for successful implementation.

How Does Just-in-Time Inventory (JIT) Work?

JIT inventory minimizes stock levels while maximizing efficiency. Instead of stockpiling materials, manufacturers order components only when needed for production, reducing storage costs and waste. For instance, a car manufacturer using JIT keeps minimal parts on hand, relying on suppliers to deliver components just in time for assembly after receiving a customer order. This method prevents overproduction and unnecessary inventory buildup.

Successful JIT implementation requires steady demand, reliable suppliers, efficient production processes, and high-quality standards to ensure smooth operations.

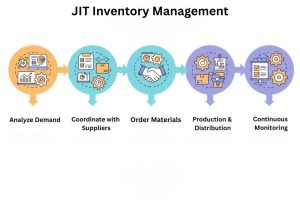

Steps in JIT Inventory Management

- Analyze Demand: Use historical data and market trends.

- Coordinate with Suppliers: Ensure fast, reliable deliveries.

- Order Materials: Only when production or sales require them.

- Production & Distribution: Inventory moves immediately into use.

- Continuous Monitoring: Track inventory in real time for adjustments.

Benefits of JIT Inventory Management

JIT reduces costs and waste by eliminating excess inventory and lowering storage expenses. It enhances efficiency by streamlining operations, ensuring materials are available precisely when needed. Businesses also gain flexibility, allowing them to quickly adapt to changes in market demand, improving responsiveness and competitiveness.

Just-in-Time (JIT) Advantages and Disadvantages

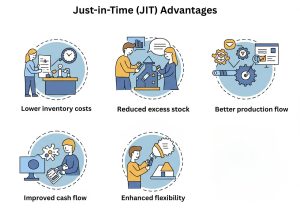

Advantages:

- Lower inventory costs: Reduces storage expenses and frees up working capital.

- Reduced excess stock: Minimizes waste by ordering materials only when needed.

- Better production flow: Improves efficiency by ensuring materials arrive just in time for manufacturing.

- Improved cash flow: Businesses avoid tying up funds in excess inventory.

- Enhanced flexibility: Quickly adapts to market demand changes and production needs.

Disadvantages:

- Supply chain dependency: Any disruption can halt production.

- Risk of delays: Late supplier deliveries can impact operations.

- Increased reliance on accurate forecasting: Requires precise demand predictions to avoid stock shortages.

- Higher operational risks: A sudden spike in demand may lead to production bottlenecks.

- Limited buffer stock: No excess inventory to handle unexpected supply chain issues.

Techniques Involved in JIT Inventory Methodology

- Demand-Driven Replenishment: Inventory is ordered only when needed, reducing excess stock and storage costs.

- Supplier Integration: Businesses establish strong relationships with vendors to ensure timely deliveries and prevent production delays.

- Lean Manufacturing: Focuses on continuous improvement and eliminating inefficiencies in production processes.

- Kanban System: A visual tool used to signal inventory needs, maintaining a smooth workflow without overstocking.

- Automation & Real-Time Tracking: Uses ERP systems, AI, and RFID tracking for accurate inventory management and demand forecasting.

- Standardized Work Processes: Establishes clear protocols for ordering, receiving, and using materials to ensure consistency and efficiency.

- Cross-Training Employees: Prepares workers for multiple roles, increasing flexibility in adapting to changes in demand.

- Contingency Planning: Develops backup plans to handle supply chain disruptions and unexpected market fluctuations.

What Is Just-in-Time Manufacturing?

Just-in-Time (JIT) manufacturing is a production method where materials and products are ordered and delivered only when needed, rather than being stored in large amounts. This helps reduce waste, lower storage costs, and make production more efficient. By using JIT, businesses avoid keeping extra inventory, which saves money and space. It also helps manufacturers work faster and adapt to changes in demand, ensuring products are made exactly when customers need them.

However, JIT requires careful planning and reliable suppliers, because any delay in deliveries can slow down production.

Is Just-in-Time Manufacturing Risky?

While JIT offers efficiency and cost savings, it also comes with risks that businesses must carefully manage. Since JIT relies on minimal inventory, any disruption in the supply chain can quickly halt production. Companies using JIT must anticipate challenges and develop contingency plans to maintain smooth operations.

Risks of JIT Inventory Management

- No buffer stock: Vulnerable to sudden demand spikes.

- Supplier dependency: Delays can halt production.

- Unpredictable demand: Requires accurate forecasting.

Impact of Supply Chain Disruptions

- Late deliveries: Slow down operations.

- Material shortages: Can lead to production stoppages.

- Logistics issues: Transport delays affect inventory flow.

Strategies to Reduce Risks

- Diversify suppliers: Avoid reliance on a single vendor.

- Improve forecasting: Use AI and analytics for demand accuracy.

- Create contingency plans: Prepare backup inventory and sourcing options.

Which Industry Types Choose JIT?

Industries That Benefit from JIT

- Automotive: Companies like Toyota use JIT to minimize inventory costs and improve production efficiency.

- Electronics: Manufacturers reduce excess stock and optimize production based on demand.

- Retail: Businesses order stock as needed, lowering storage and handling expenses.

Why Businesses Choose JIT

- Cost Efficiency: Reduces storage costs and unnecessary inventory.

- Operational Flexibility: Adjusts quickly to changing market demand.

- Improved Production Flow: Ensures a smooth and streamlined manufacturing process.

Who Invented JIT Inventory Management?

Just-in-Time (JIT) inventory management was developed by Toyota in the 1970s as part of its Toyota Production System (TPS). Influenced by Japanese manufacturing efficiency and the goal of eliminating waste, JIT ensures materials are delivered only when needed, reducing excess inventory and costs. Taiichi Ohno, a Toyota engineer, played a key role in refining this approach, helping the company achieve faster production cycles and improved efficiency.

Over time, JIT revolutionized global industries, with companies worldwide adopting the system to streamline operations, enhance flexibility, and optimize resources.

Conclusion

Just-in-Time (JIT) inventory management enhances efficiency, reduces waste, and lowers costs by ensuring materials arrive only when needed. While JIT offers flexibility and improved production flow, it requires strong supplier coordination, accurate demand forecasting, and contingency planning to manage risks. Businesses that adopt best practices—such as leveraging technology and maintaining reliable supplier networks—can maximize JIT benefits and stay competitive in dynamic markets.

If you liked this article, don’t forget to subscribe to our newsletter to get more exciting articles, news, and offers right in your inbox. Also, follow us on Facebook, Instagram, and Dribble to stay updated.

FAQ’s for JIT

1. What is Just-In-Time (JIT)?

JIT is an inventory and production strategy that minimizes waste by ordering or producing goods only when needed.

2. How does JIT improve efficiency?

JIT reduces storage costs, improves cash flow, and enhances responsiveness to market demand.

3. What industries use JIT?

JIT is widely used in manufacturing, retail, and logistics to optimize inventory and reduce excess stock.

4. What are the risks of JIT?

Supply chain disruptions can lead to delays, and businesses must rely on accurate demand forecasting.

5. How does JIT affect suppliers?

Suppliers must be highly responsive and capable of delivering materials quickly to support JIT operations.

6. Can small businesses use JIT?

Yes, small businesses can implement JIT to reduce inventory costs and improve operational efficiency.

7. What is the difference between JIT and traditional inventory management?

Traditional inventory management involves stocking large quantities, while JIT focuses on ordering only when needed.

8. How does JIT impact customer satisfaction?

JIT ensures timely product availability, reducing delays and improving service quality.

9. What technologies support JIT?

Automation, AI-driven demand forecasting, and real-time inventory tracking help businesses implement JIT effectively.

10. How can businesses transition to JIT?

Companies should analyze demand patterns, strengthen supplier relationships, and invest in efficient logistics systems.